Design of an Ecological Visual Analytics Interface for Operators of Time-Constant Processes

Elmira Zohrevandi, Emmanuel Brorsson, Andreas Darnell, Magnus Bång, Jonas Lundberg, Anders Ynnerman

Room: 104

2023-10-25T05:39:00ZGMT-0600Change your timezone on the schedule page

2023-10-25T05:39:00Z

Fast forward

Full Video

Keywords

Visual analytics interfaces, Design study, Focus+context techniques, Linked-view interfaces, Time-constant processes

Abstract

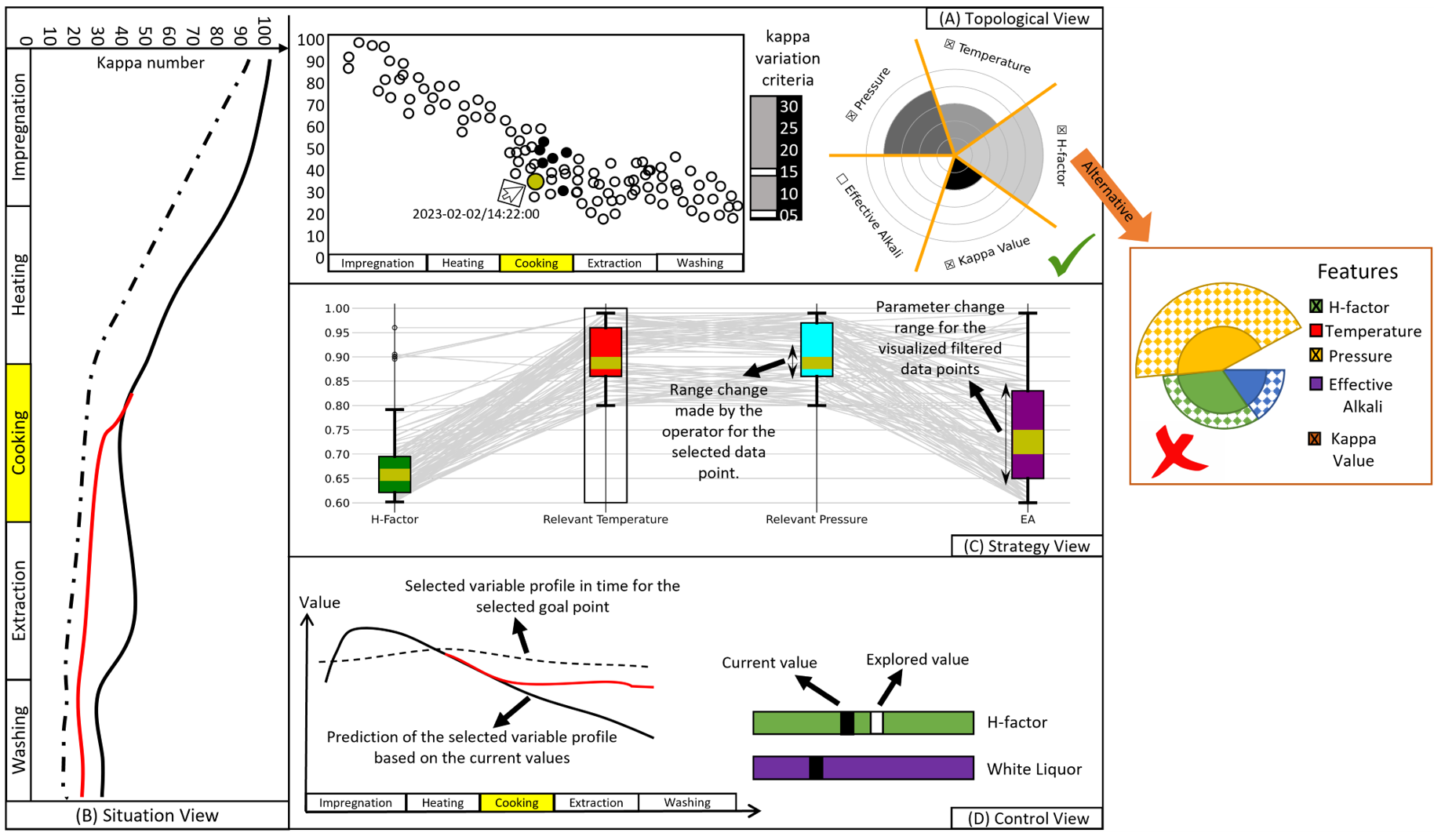

In industrial applications where the physical parameters are highly interconnected, keeping the process flow steady is a major concern for the operators. This is caused by the sensitivity of system to the process dynamics. As a result, a slight adjustment to a control parameter can significantly affect the efficiency of the system and thus impact the financial gain. Paper pulp production is an example of such a process, where operators continuously investigate the potential of changes in the process and predict the consequences of an adjustment before making a decision. Process parameter adjustments prescribed by simulated control models cannot be fully trusted as the external disturbances and the process inherent variabilities cannot be fully incorporated into the simulations. Therefore, to assess the viability of a strategy, operators often compare the situation with the historical records and trends during which the processes in the plant ran steadily. While previous research has mostly focused on developing advanced control models to simulate complex pulp production process, this work aims to support operators analytical reasoning by provision of effective data visualization. The contributions of our design study include a domain problem characterization and a linked-view visual encoding design, which aims to enhance operator's mental models independent of particular users or scenarios. Finally, by reflecting on the advantages of our choice of task abstraction technique, inherited from the ecological interface design framework [5], we reason for the generalizability of our approach to similar industrial applications.